Warning

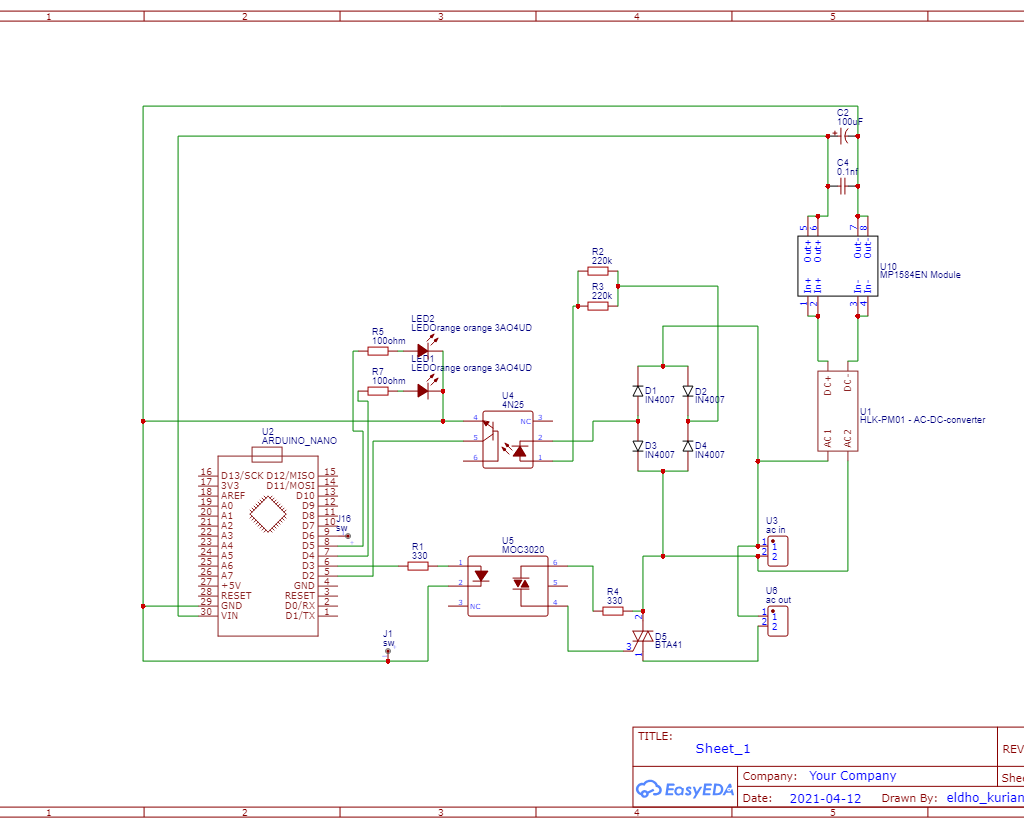

This project deals with high voltage

Description

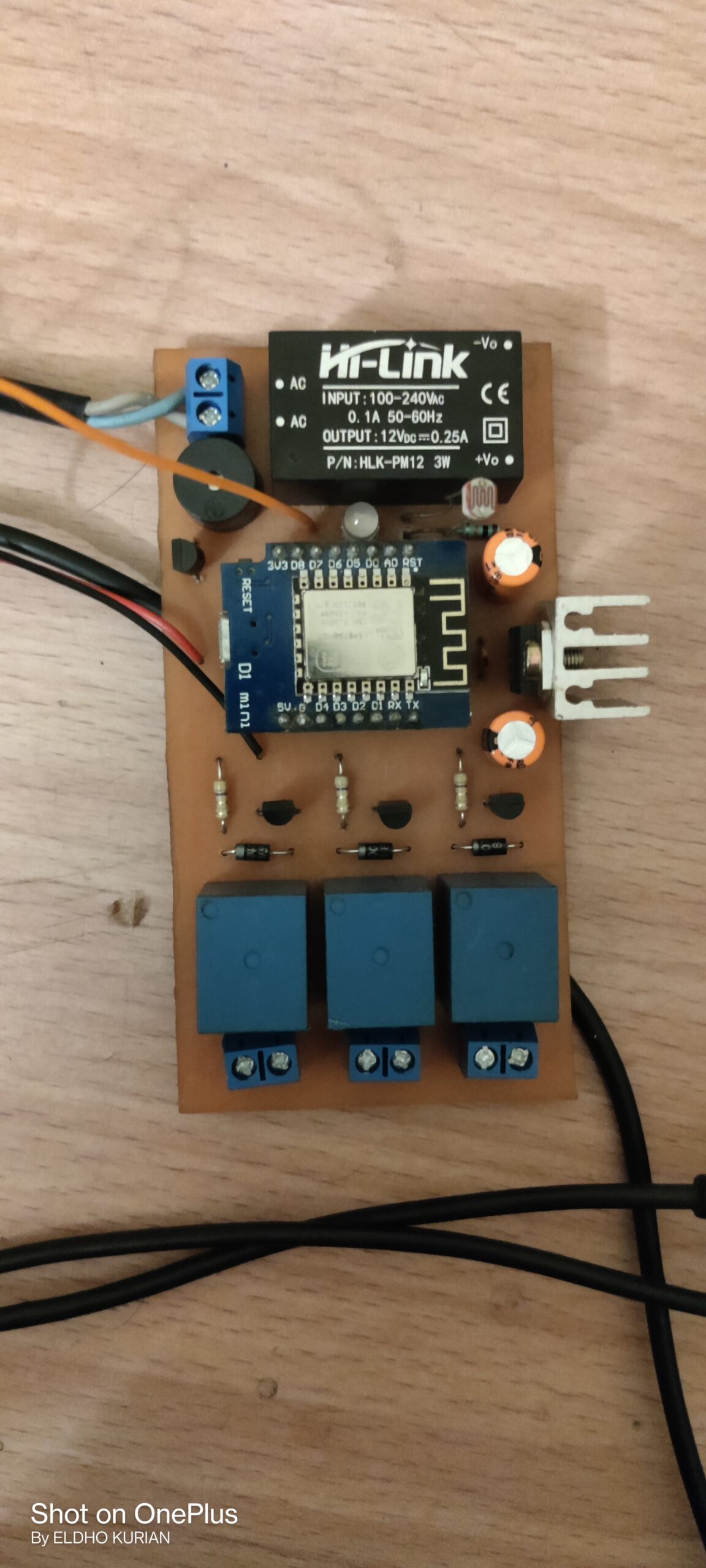

The purpose of this project is to create an innovative device that can be controlled using Amazon Alexa voice commands, allowing users to control up to three appliances with ease. The device will have three relays, which can be linked to any three appliances, providing users with a convenient way to automate their home or office.

The device will be designed to be compatible with most appliances and will be easy to install, with no complicated wiring required. Once installed, users can connect the device to their Wi-Fi network and link it to their Alexa account, enabling them to control their appliances using voice commands.

In addition to voice control, the device will also come with a mobile app that users can use to control their appliances remotely. This app will enable users to set schedules and timers for their appliances, making it easier to manage their daily routines.

The device will be built to last, with a durable and sleek design that looks great in any setting. It will also be designed with safety in mind, with features such as automatic shut-off.

Overall, this project aims to create a practical and convenient solution for users to control their appliances using voice commands. With its compatibility with most appliances and ease of use, this device will make life simpler and more efficient for users in their daily routines.

How to set up

- power on device and search for the WIFI created by it in your pc or phone

- connect to that WIFI and you will be greeted by a web page

- search for your home WIFI it and connect with it

- the web page should show if it was connected successfully

- go to the Alexa app and search for new devices(just like setting a Philips smart light bulb)

- complete the setup process and you are ready to go

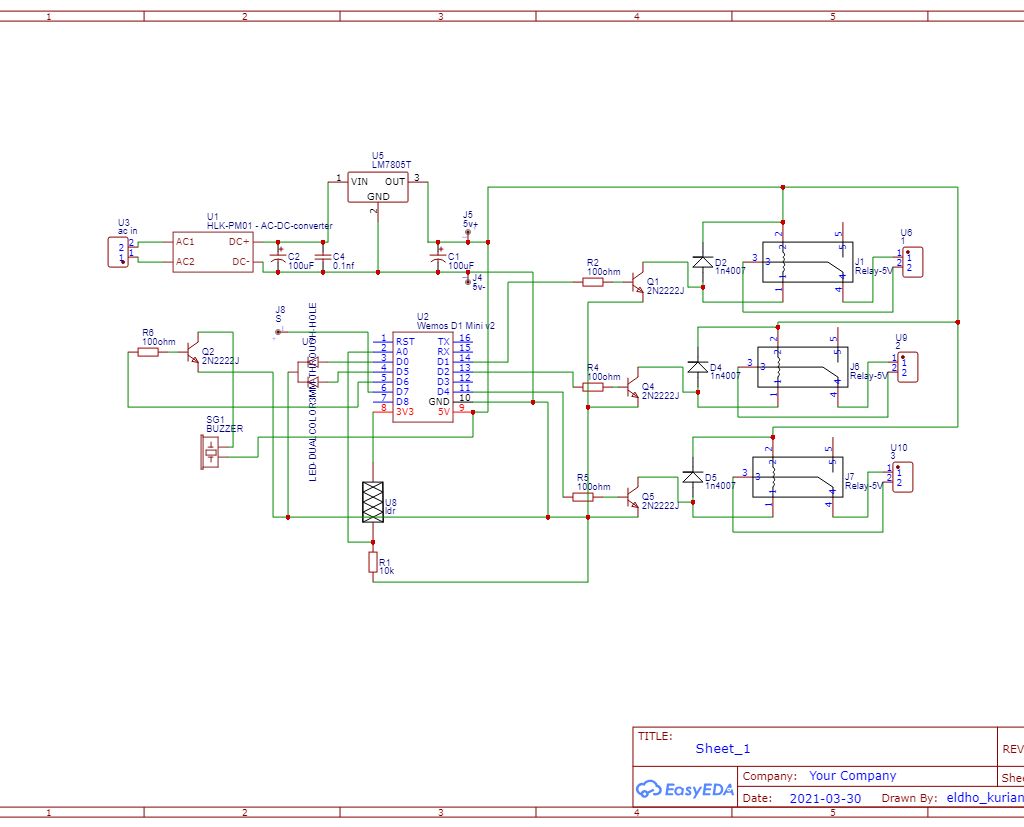

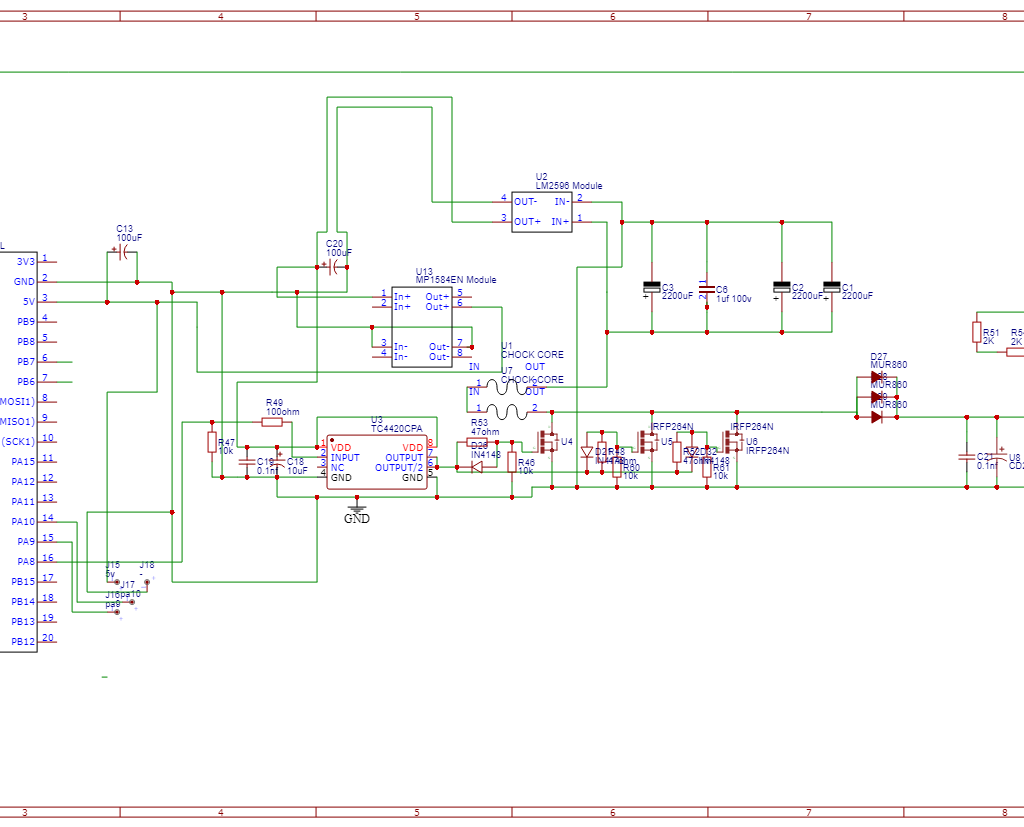

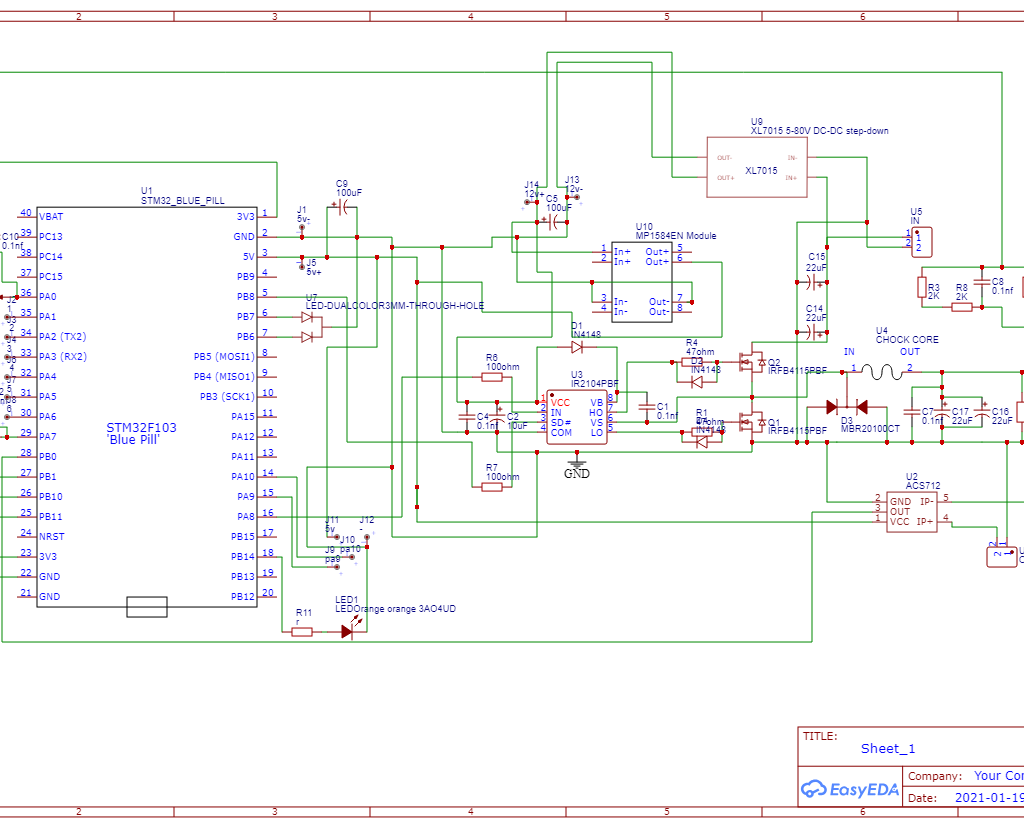

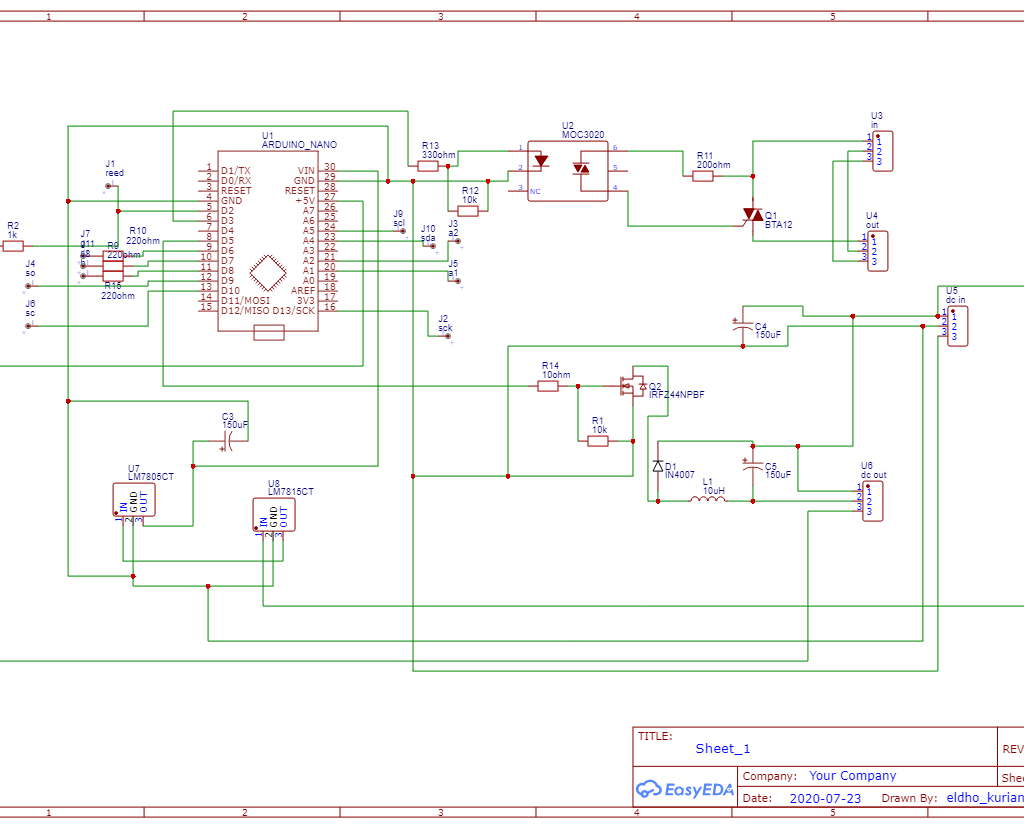

Schematic